Acme corporation

Acme is the best

The finest in this field

Acme Corporation™ is the world’s leading manufacturer of digital shapes. From squares and circles to triangles and hexagons, we have it all. Browse through our collection of various forms with different thicknesses and line styles.

Personalized especially for you

We convert dreams into designs. Our artists are one of a kind. We provide full support for customizing your designs with multiple contact sessions to understand your problems and get a satisfying result.

Subsections

Posts

About Us

Acme Corporation™ is the world’s leading manufacturer of digital shapes. From squares and circles to triangles and hexagons, we have it all. Browse through our collection of various forms with different thicknesses and line styles. ☺ We shape the world. You live in it. ☺ We provide 😄 to hundreds of happy customers. Manufacturing At Acme Corporation, we take pride in what we create. Our manufacturing process goes through 3 different stages of fine workmanship to give you the best possible shapes. Read More

Our Manufacturing Process Part IV

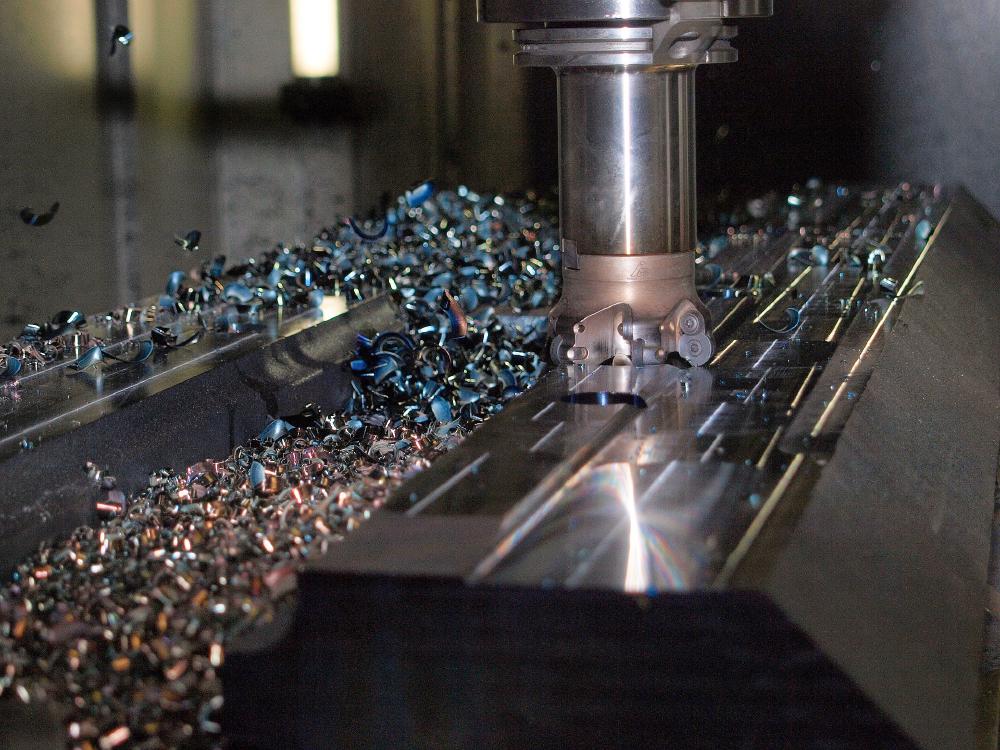

A cutting tool has one or more sharp cutting edges and is made of a material that is harder than the work material. The cutting edge serves to separate chip from the parent work material. Connected to the cutting edge are the two surfaces of the tool: The rake face; and The flank. The rake face which directs the flow of newly formed chip, is oriented at a certain angle is called the rake angle “α”. Read More

Our Manufacturing Process Part III

Machining is any process in which a cutting tool is used to remove small chips of material from the workpiece (the workpiece is often called the “work”). To perform the operation, relative motion is required between the tool and the work. This relative motion is achieved in most machining operation by means of a primary motion, called “cutting speed” and a secondary motion called “feed”.[7] The shape of the tool and its penetration into the work surface, combined with these motions, produce the desired shape of the resulting work surface. Read More